Description

Description

Our customer wanted to upgrade their existing effluent treatment plant control system from a fully manual operation with many obsolete components through a phased approach to eventually reach full automation.

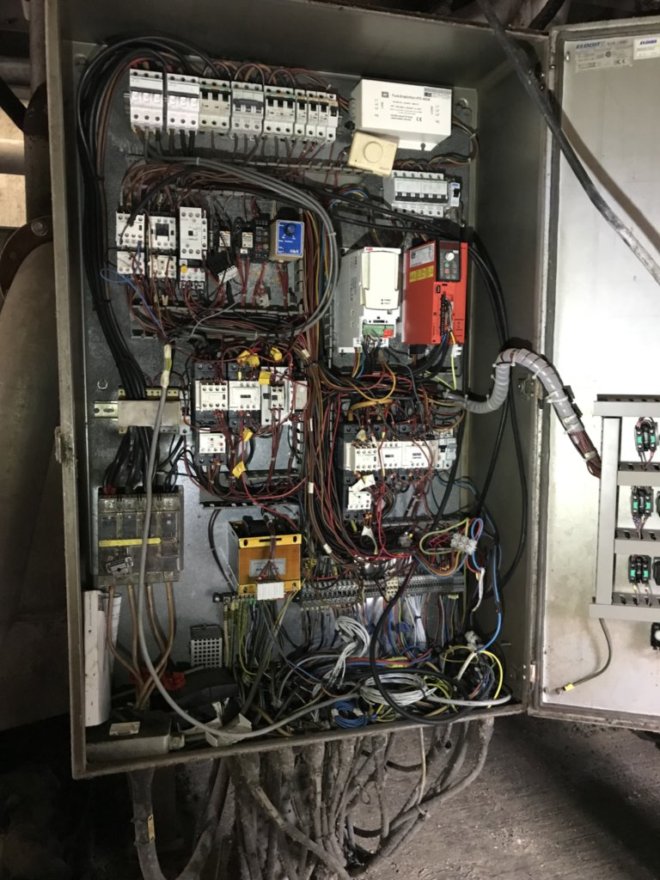

The second phase involved the design, build, installation and commissioning of replacement control systemsfor the Primary DAF (Dissolved Air Flotation) and Secondary DAF Systems. As you can see from the photograph of part of one of the systems below, these control systems were in desperate need of a replacement as they had suffered a reasonably hard life due to the atmosphere in which they were installed.

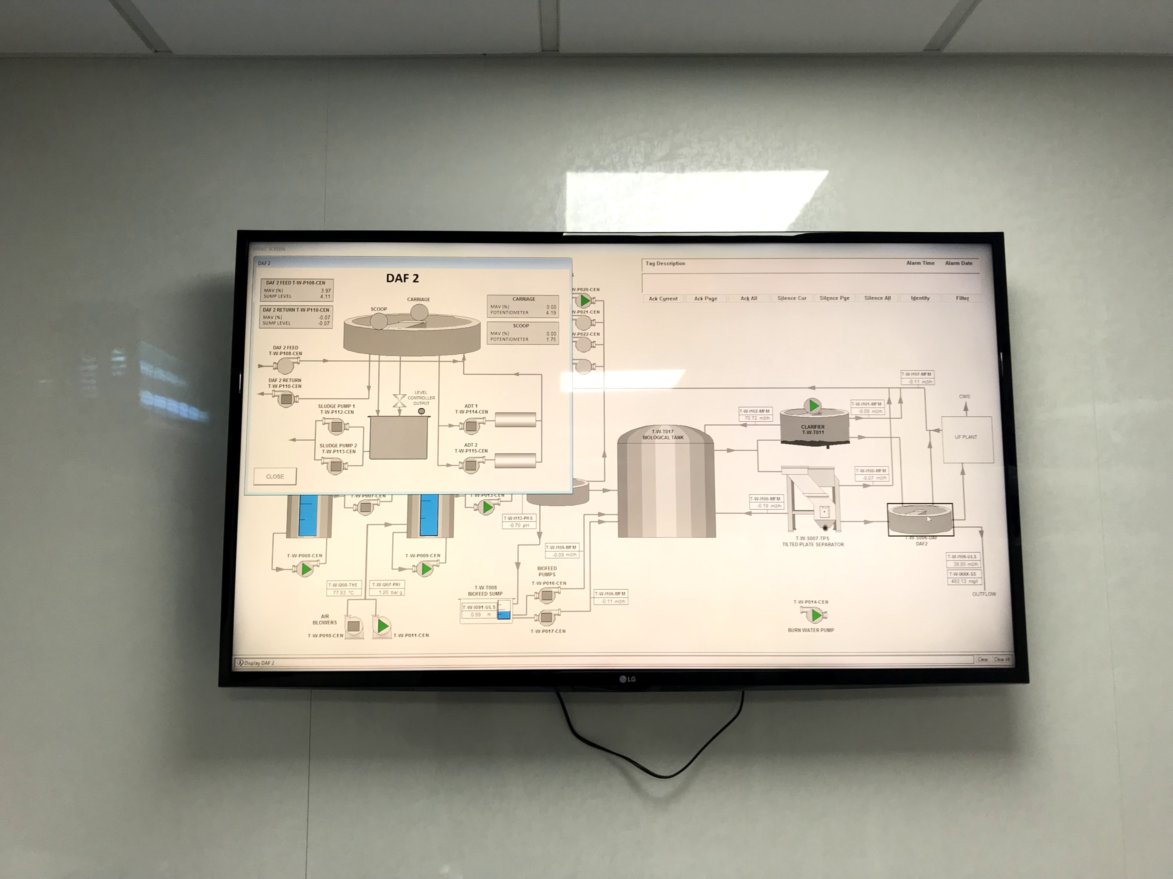

The decision was taken to move the control elements outside of the buildings housing the two DAF units. For longevity, a GRP housing in which to locate each control panel was proposed by us and accepted by our customer. An Emergency Stop station and manual Carriage and Scoop speed control potentiometers were positioned indoors for ease of set up by eye.

The control panels were designed to interface with the control system installed in phase 1 of the project, so that all elements could be controlled using the site SCADA that we provided during phase 1. The DAF units are able to operate automatically, and the integration with the main control system means that these replacement systems are ready to support full automation of the plant.

Allen Bradley Point IO was used to integrate seamlessley with the Allen Bradleg CompactLogix in the main panel. Danfoss Drives and Softstarters were selected as they were the site standard and this allows our customer to hold less spares.

Client:

Scottish Tannery Effluent Treatment Plant

Location:

Scotland

Recent Comments