Description

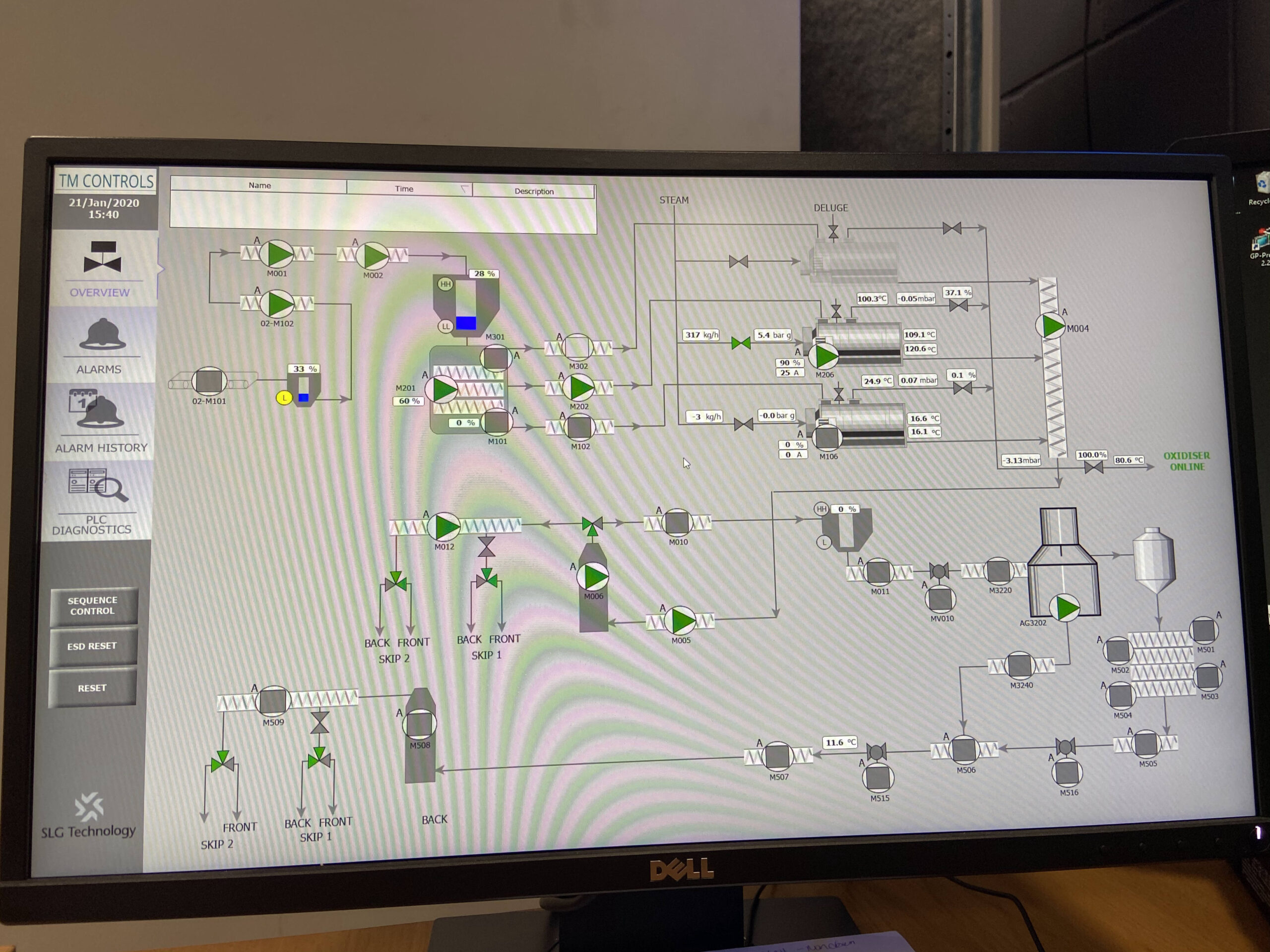

Our customer was upgrading their plant to include a brand new material handling system feeding three new rotary steam heated dryers. We were tasked with developing a system to control the 24 new screw conveyors, exisiting belt feed conveyor, numerous valves and the three new dryers. This needed to link seamlessly in to the control of a gasifier to which the dried material is fed, and an oxidiser which takes the exhaust emissions from the dryers.

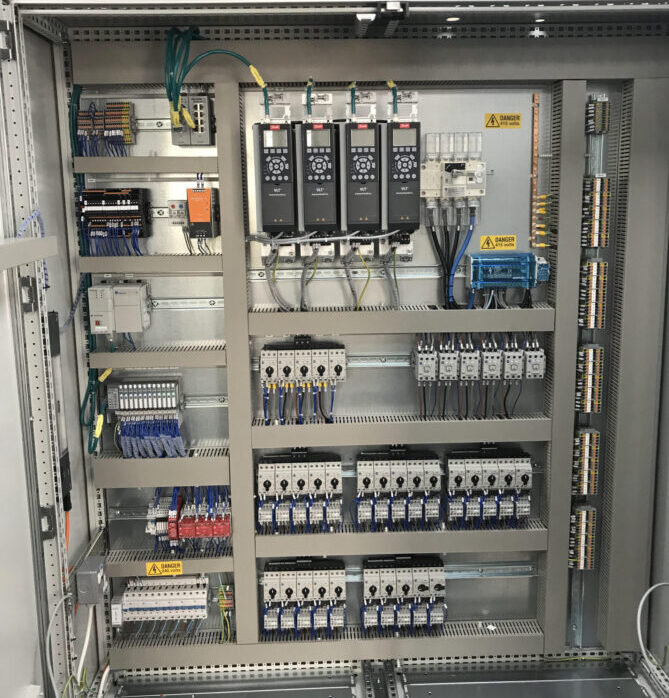

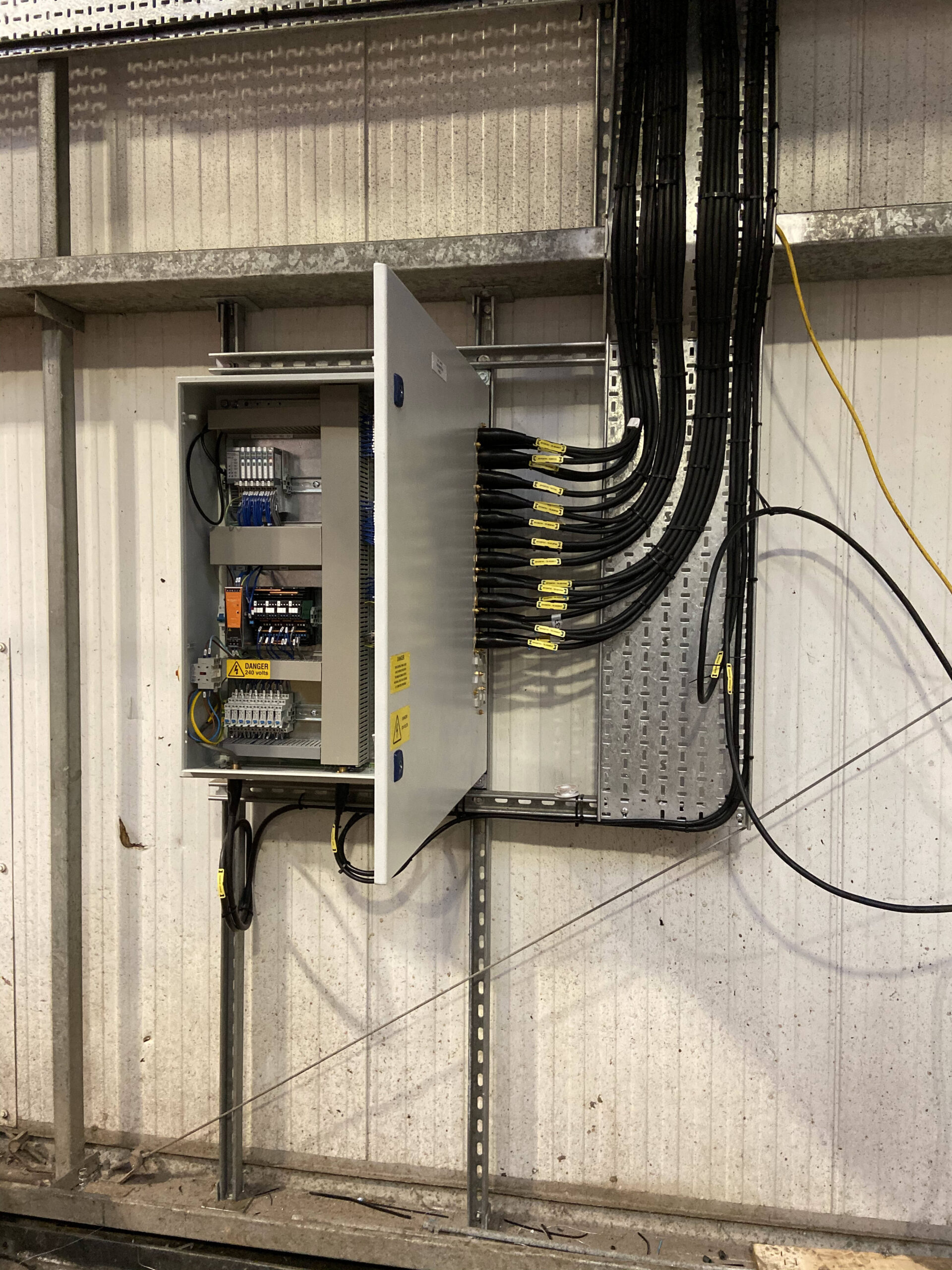

The system was based on an Allen Bradley PLC platform – CompactLogix with remote IO in the various areas of the plant. As a site standard, Danfoss Drives and Softstarters were used, with Allen Bradley motor starters for those motors the were fixed speed and lower duty.

We provided full installation services which involved all cable containment, 5km of cable and countless cable ties. A full, user friendly HMI was provided with appropriate diagnostics and allowing full control. A mobile HMI was also provided, allowing maintenance personnel to take it with them when making any repairs.

Client:

Scottish Tannery Waste Processing Plant

Location:

Scotland

Recent Comments