Our in house engineers have considerable experience in the development of software on PLCs from all major manufacturers. Coupled with the ability to assess and select the right technology for your application, this means that we can provide bespoke programming to fulfil your needs. With a scope ranging from Entry Level PLCs right through to the use of high level Safety PLCs, we can offer a programming service for either original concept and design or upgrade of an existing system.

As our team includes Functional Safety and Chemical Engineers, we can also provide you with a Functional Design Specification, Control Narrative, Logic Diagram and Safety Validation Report when required, and assist you with the design and development of automating your system.

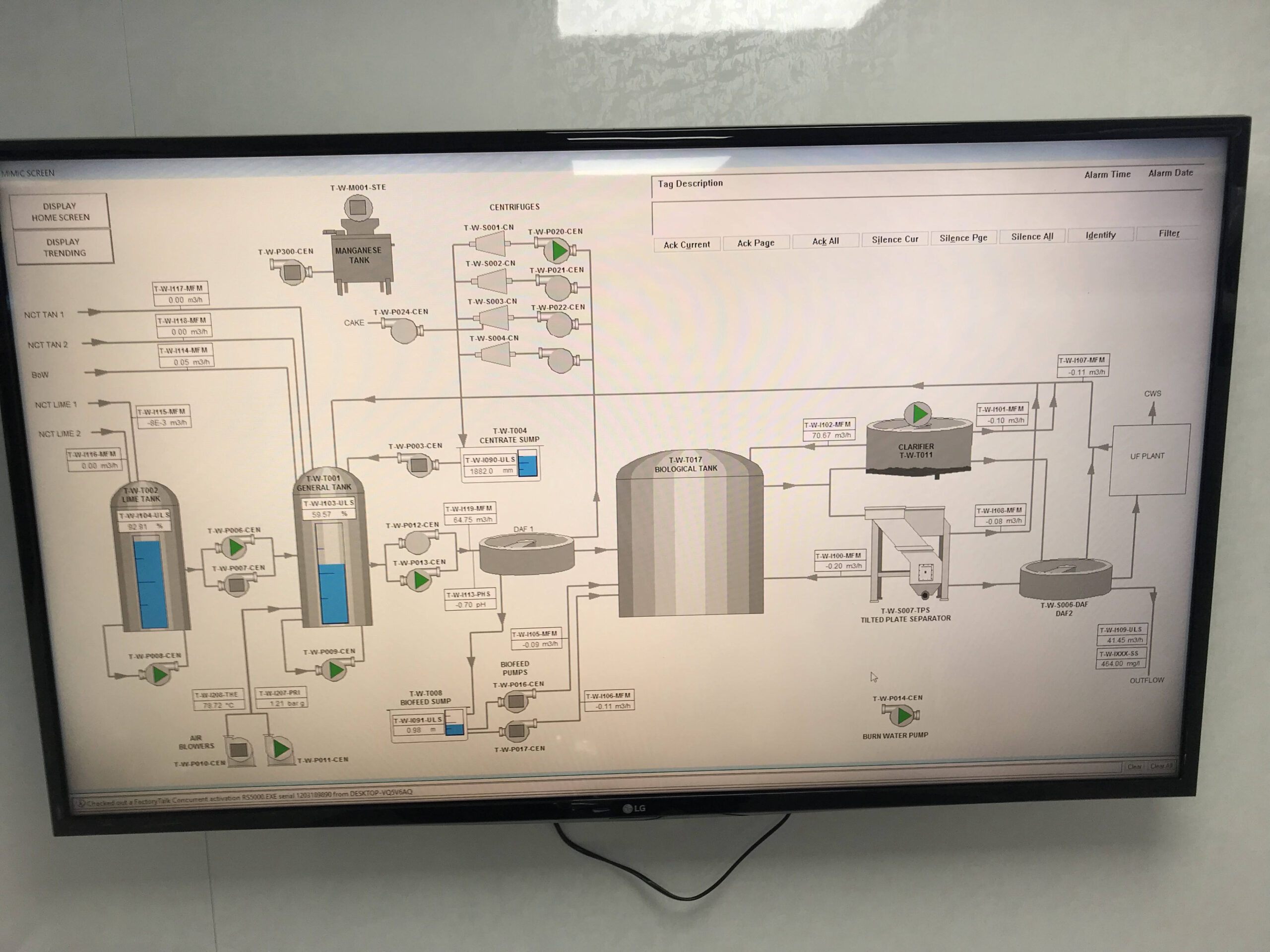

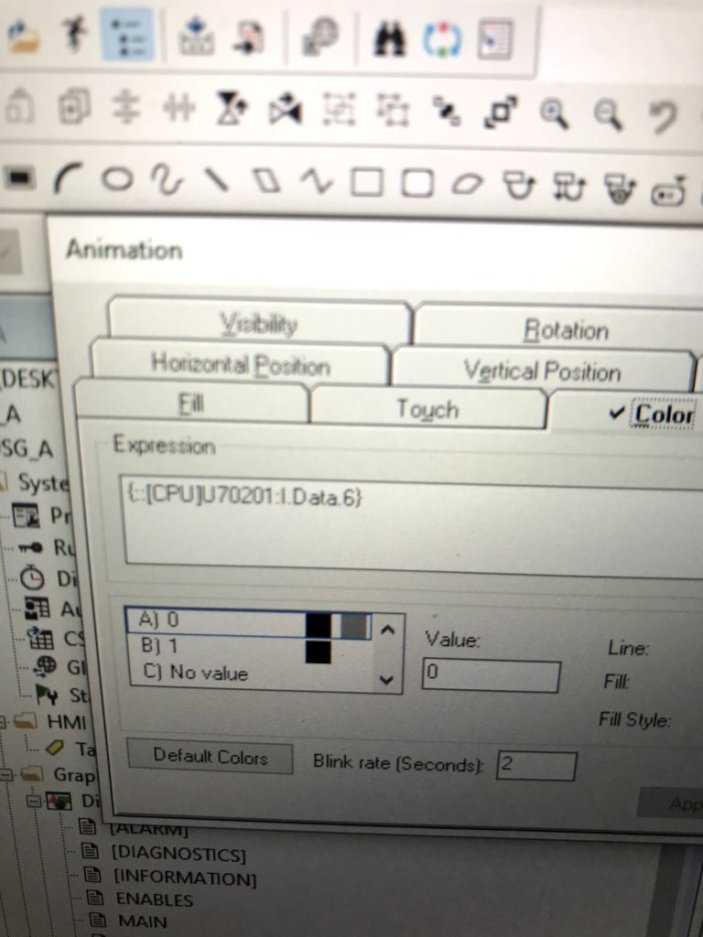

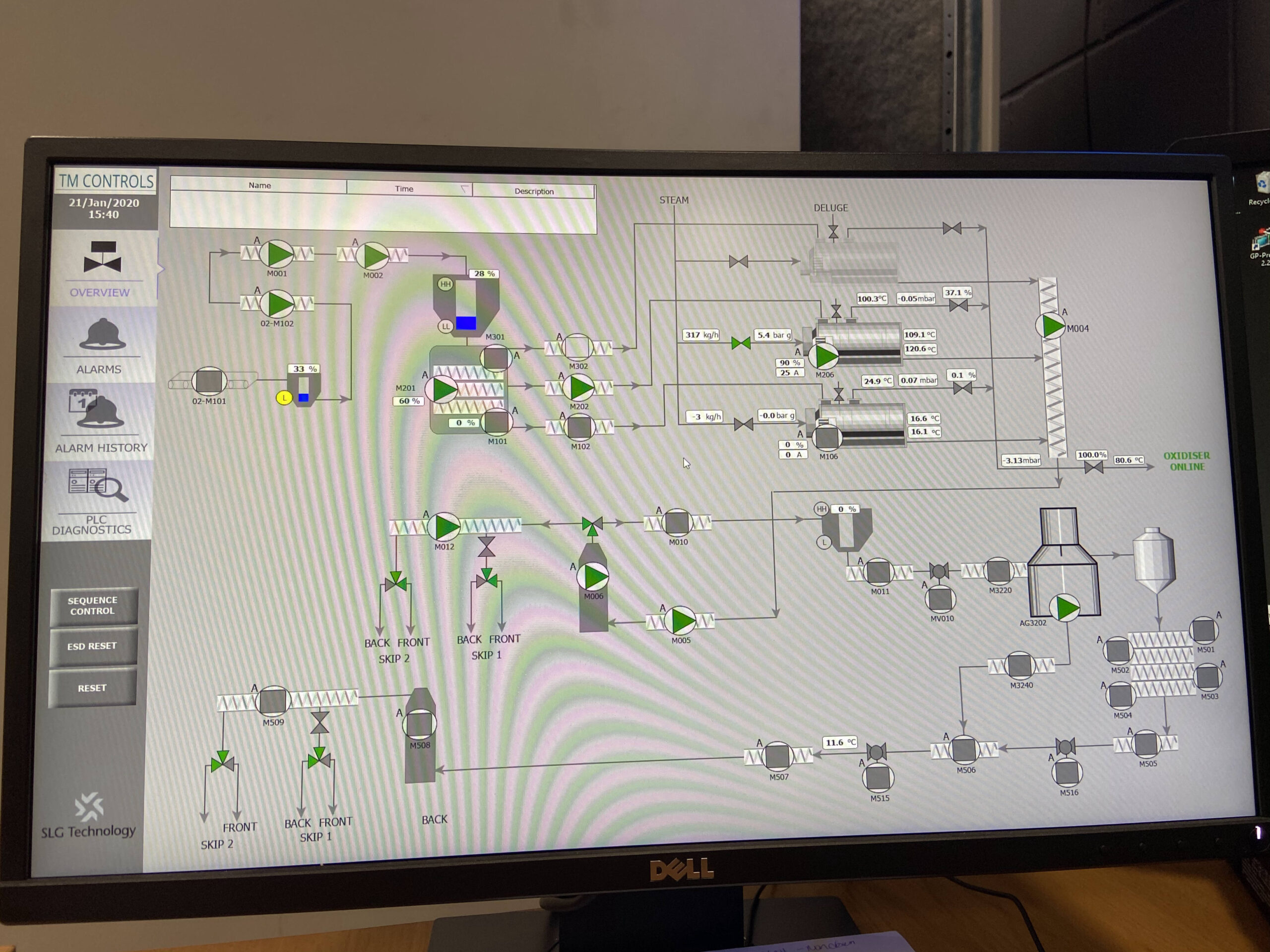

For visualisation, we can use the same HMI or SCADA manufacturer as the PLC platform, or we can offer seamless integration and communication on a range of third party interfaces, including EXOR and ProFace. As we have an excellent understanding of your process, we are able to develop user friendly systems which fully address the needs of both operators and on site engineers for opertion and maintenance purposes.

PLC, HMI and SCADA platforms that we have experience with include (but are not limited to):

- Siemens – all PLC’s including F and FH Safety Systems using Step 7 Classic and TIA Portal, HMI and WINCC SCADA

- Rockwell Automation – Allen Bradley (ControlLogix, CompactLogix, MicroLogix, FactoryTalk HMI and SCADA etc), AADvance (formerly ICS Triplex)

- Emerson – DeltaV

- Exor – HMI

- GE iFIX – SCADA

- Wonderware – SCADA

Recent Comments